Frequently Asked Questions (FAQ)

FAQ CATEGORIES

Common Pre-Purchase Questions

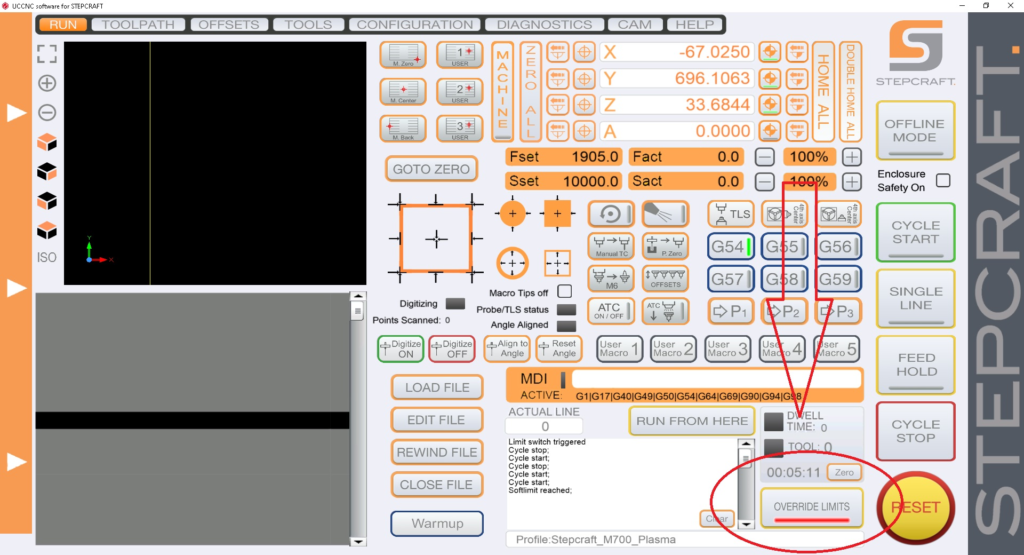

If an error has occurred or your system has an obstruction causing the Semi-Closed Loop System to trigger, it will activate the E-Stop mode on the machine. When this happens the first thing you need to do is take note of the line number that you are at in the G-Code window on the lower left part of the UCCNC screen. Write it down or take a photo with your cell phone.

To reset this, you press the Red reset button on the UCCNC screen and then press HOME ALL. This will reset each axis so that everything is back in sync with UCCNC. From that point, you can use the START FROM HERE button and restart the job from right where you left off.

You can view this video on how to use the START FROM HERE button:

Hardware Troubleshooting

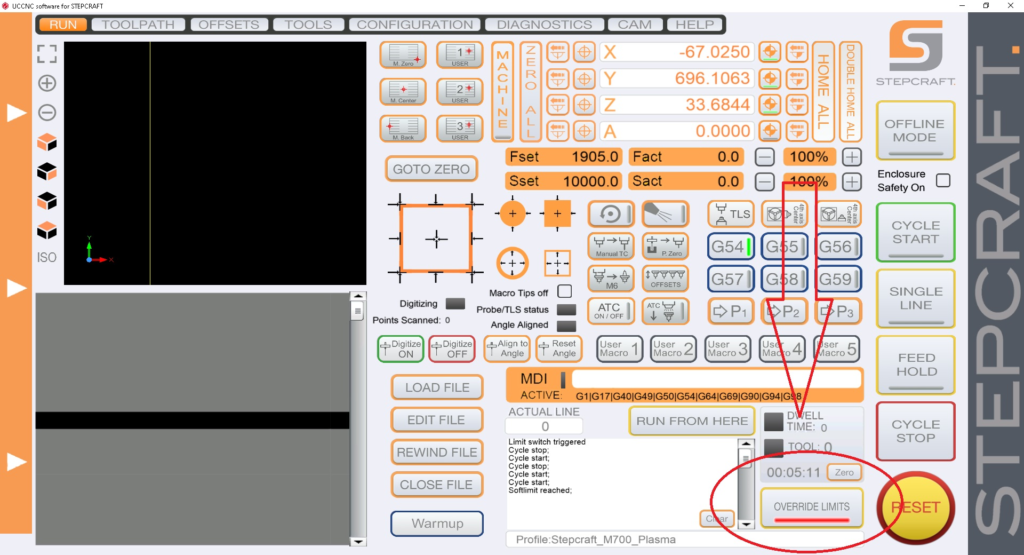

When you home your machine, if the Z axis moves down towards the bed, it means you have a limit switch triggered somewhere on your machine and you have used the “Override Limits” button to reset and move the machine. If you try to Home the machine with the “Override Limits” button active, the Z-Axis will move straight down until it eventually crashes into the bed.

The “Override Limits” button is only to allow you to reset and jog the machine off any limit switch that may currently be engaged. Once the limit switch is disengaged, the “Override Limits” button will no longer flash red and you can home the machine. Another method to clear the switch is to engage your physical E-Stop button, which will cut power to the motors and allow you to turn the lead screws by hand to physically disengage the limit switch. For example, if your Z-Axis is on a switch and is all the way up, you can turn the screw about 1-2 turns until it is no longer activating the switch.

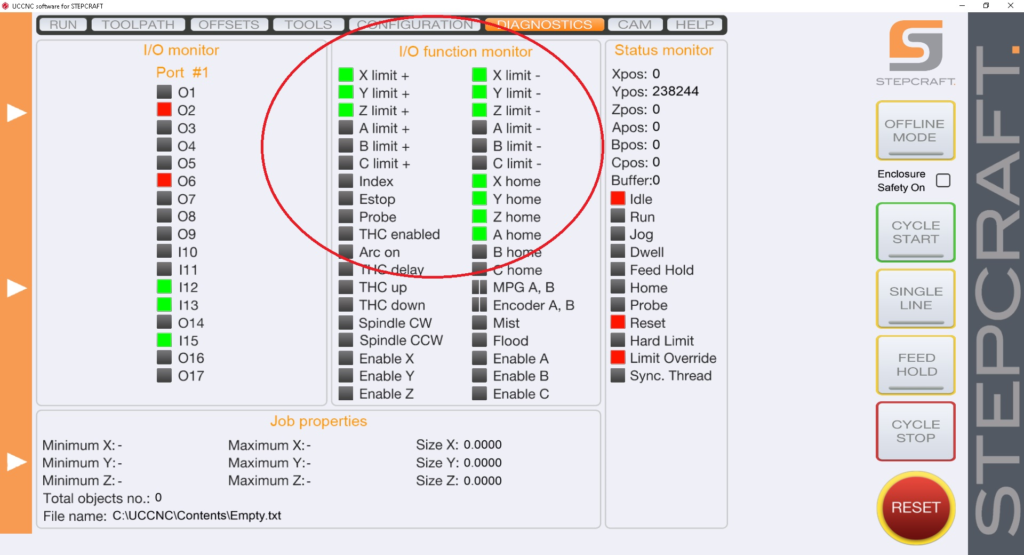

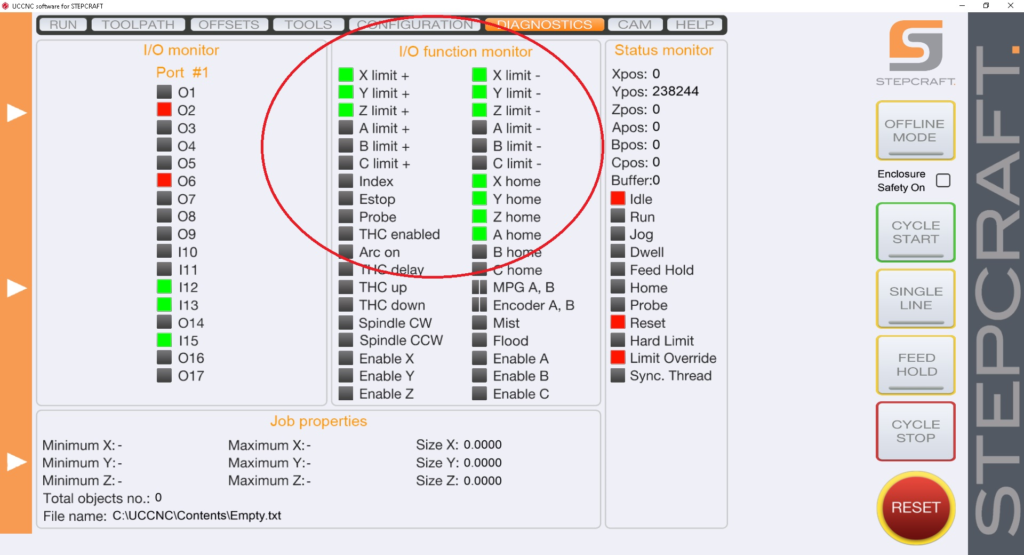

You can tell if a limit switch is currently active in your diagnostics screen in UCCNC. Below is an example of a machine with a limit switch currently active (green).

Note that the X, Y and Z limit switches are all on the same circuit, so when one is active all will show in UCCNC as active. This does NOT mean all three are active.

When you press E-Stop or power off your machine, it is possible that the Z axis can lower under its own weight towards the machine bed. This is most common on Q-Series machines with the ATC-2200 spindle and on M-Series machines that are equipped with ball screws.

Why does it happen? The ball screw system on the M and Q machines was designed for very smooth operation to allow the Z motor to be very responsive and provide excellent resolution. There is very little friction in the Z axis assembly on a ball screw machine. Because of this, the weight of the spindle can naturally cause the Z-axis to lower under its own weight when the Z-axis motor is not energized.

How do I resolve this? On the M-Series machines, there really is no direct resolution for this. You should make common practice on any CNC system to home all axes when you power the machine on or before you start using your machine on a given day. This way you can always be sure all your axes’ positions are recognized by the software and this is the best way to ensure that you have no issues with your Z height during your jobs.

Additionally, you should make sure you remove the tool holder (on Automatic Tool Changer spindles) before you power the machine down or remove the end mill from non-ATC spindles. Additionally, you can place something to support the Z Axis under it, such as a block of wood to prevent it from falling all the way to the table.

On the Q-Series machines, we have a solution that can resolve this issue as well as increase the performance of your Z axis during rapid Z operations such as when 3D carving. Please contact support@stepcraft.us for more info on this. Outside of this, the same applies to the Q as with the M, you should make it a common practice to home all your axes when you power on the machine or at the start of your work day.

On average you will see 125-150 hours of use on your MM-1000 DI spindle before you start to see signs that it is time to change them.

These signs can include:

sign 1

sign 2

You can order a replacement set from our website HERE.

If an error has occurred or your system has an obstruction causing the Semi-Closed Loop System to trigger, it will activate the E-Stop mode on the machine. When this happens the first thing you need to do is take note of the line number that you are at in the G-Code window on the lower left part of the UCCNC screen. Write it down or take a photo with your cell phone.

To reset this, you press the Red reset button on the UCCNC screen and then press HOME ALL. This will reset each axis so that everything is back in sync with UCCNC. From that point, you can use the START FROM HERE button and restart the job from right where you left off.

You can view this video on how to use the START FROM HERE button:

Maintenance

On average you will see 125-150 hours of use on your MM-1000 DI spindle before you start to see signs that it is time to change them.

These signs can include:

sign 1

sign 2

You can order a replacement set from our website HERE.

Software Troubleshooting

When you home your machine, if the Z axis moves down towards the bed, it means you have a limit switch triggered somewhere on your machine and you have used the “Override Limits” button to reset and move the machine. If you try to Home the machine with the “Override Limits” button active, the Z-Axis will move straight down until it eventually crashes into the bed.

The “Override Limits” button is only to allow you to reset and jog the machine off any limit switch that may currently be engaged. Once the limit switch is disengaged, the “Override Limits” button will no longer flash red and you can home the machine. Another method to clear the switch is to engage your physical E-Stop button, which will cut power to the motors and allow you to turn the lead screws by hand to physically disengage the limit switch. For example, if your Z-Axis is on a switch and is all the way up, you can turn the screw about 1-2 turns until it is no longer activating the switch.

You can tell if a limit switch is currently active in your diagnostics screen in UCCNC. Below is an example of a machine with a limit switch currently active (green).

Note that the X, Y and Z limit switches are all on the same circuit, so when one is active all will show in UCCNC as active. This does NOT mean all three are active.

If an error has occurred or your system has an obstruction causing the Semi-Closed Loop System to trigger, it will activate the E-Stop mode on the machine. When this happens the first thing you need to do is take note of the line number that you are at in the G-Code window on the lower left part of the UCCNC screen. Write it down or take a photo with your cell phone.

To reset this, you press the Red reset button on the UCCNC screen and then press HOME ALL. This will reset each axis so that everything is back in sync with UCCNC. From that point, you can use the START FROM HERE button and restart the job from right where you left off.

You can view this video on how to use the START FROM HERE button:

Spindles and Routers

On average you will see 125-150 hours of use on your MM-1000 DI spindle before you start to see signs that it is time to change them.

These signs can include:

sign 1

sign 2

You can order a replacement set from our website HERE.

STEPCRAFT Attachments and Accessories

If an error has occurred or your system has an obstruction causing the Semi-Closed Loop System to trigger, it will activate the E-Stop mode on the machine. When this happens the first thing you need to do is take note of the line number that you are at in the G-Code window on the lower left part of the UCCNC screen. Write it down or take a photo with your cell phone.

To reset this, you press the Red reset button on the UCCNC screen and then press HOME ALL. This will reset each axis so that everything is back in sync with UCCNC. From that point, you can use the START FROM HERE button and restart the job from right where you left off.

You can view this video on how to use the START FROM HERE button:

STEPCRAFT M-Series CNC Systems

If an error has occurred or your system has an obstruction causing the Semi-Closed Loop System to trigger, it will activate the E-Stop mode on the machine. When this happens the first thing you need to do is take note of the line number that you are at in the G-Code window on the lower left part of the UCCNC screen. Write it down or take a photo with your cell phone.

To reset this, you press the Red reset button on the UCCNC screen and then press HOME ALL. This will reset each axis so that everything is back in sync with UCCNC. From that point, you can use the START FROM HERE button and restart the job from right where you left off.

You can view this video on how to use the START FROM HERE button: