End Mills and Cutters

What is the best bit or end mill to use when cutting Acrylic, and what are the best speeds and feeds?

Acrylic is a very common material to cut on a CNC. It can be used for anything from making windows in projects to making edge-lit LED signs. Acrylic can be a tricky material to cut successfully, mainly because many people will run the RPM of the cutter too fast with a feed rate that is too slow, thus causing melting of the plastic. The trick is to get nice clean chips as you cut.

The following article goes into this in detail: Cutting Acrylic – 8 Guidelines To Getting The Best Results

What is a surfacing bit used for?

A surfacing bit typically has a larger than normal cutting diameter (1 to 3 inches) and are used to flatten or level uneven surfaces on your project material. They are also used to take the thickness of a material down to a final required size. For example, you might have a piece of rough cut lumber that measures 1 inch in thickness but you need it to be 3/4 inch thick. If you don’t have a surface planer in your shop then you can use a surfacing bit with a pocket tool path to plane the material down.

Another common use for surfacing bits is to clean up and level a spoil board. After continuous use your spoil board’s surface will have a lot of cuts in it and you might want to clean it up so it is perfectly smooth again. A surfacing bit is perfect for this, especially with machines where the spoil board is physically attached to the machine – you might want to prolong the use of it for as long as you can before replacing.

Leveling your spoil board is also important. If you are looking to engrave .005″ into a piece of metal and your bed is off by a couple thousandths from one side to the other or front to back, then the thickness of your engraved lines will vary. By using a surfacing bit, you will ensure that your spoil board is perfectly level in relation to your gantry which will result in a uniform engraving.

Note: Because of the larger diameter of a surfacing bit, it is important to note that you can not take as deep of passes or run as fast as you might with smaller end mills on most machines. Consult your machine’s manufacturer for assistance with proper speeds and feeds for surfacing bits.

Using a CNC machine is like an artist painting.

The material you are working on is your “canvas” and the bits (otherwise known as “end mills” or “tools”) are the “brushes”

There are literally tens of thousands of bits available for a CNC machine from hundreds of manufacturers. Getting into detail on them all would literally be a book. So for this question we will break it down into XX types:

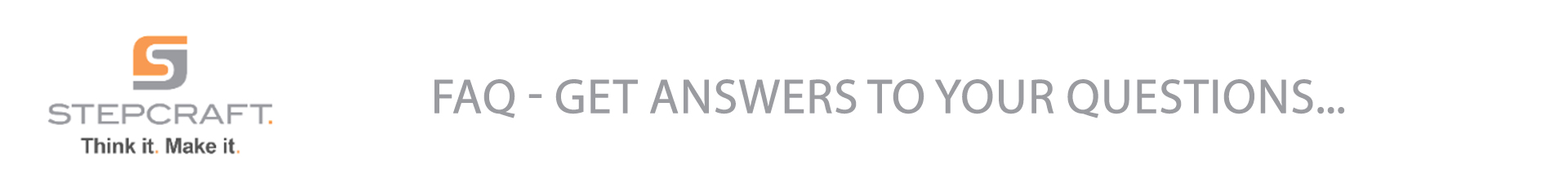

Square nose end mill – These bits are the most common and are what you would likely turn to for all of your CNC cutting. They come in a variety of shapes, sizes and spiral types. If you are just starting out, you might want to have an 1/8″ 2 flute up spiral and a 1/8″ 2 flute down spiral end mill to get you started. Both bits will work in most all CNC machines as an 1/8″ shaft diameter is very popular, even if you are using a Dremel tool as a spindle.

2 Flute is a common type since most CNC routers run at very high RPM, so you need fewer flutes to extract the chips from the material as you are cutting quickly.

Up Spiral bits will pull the chips away from the material, but can leave a frayed top edge of your workpiece, these bits are better for plastics and aluminum and harder woods.

Down Spiral bits will push the chips into the work material but will leave a very clean top edge cut. These bits are best for softer materials and wood as they leave a better finish. They also force the material down into the bed of the machine which is good for thinner materials, where an up spiral bit will tend to pull it away from the bed.

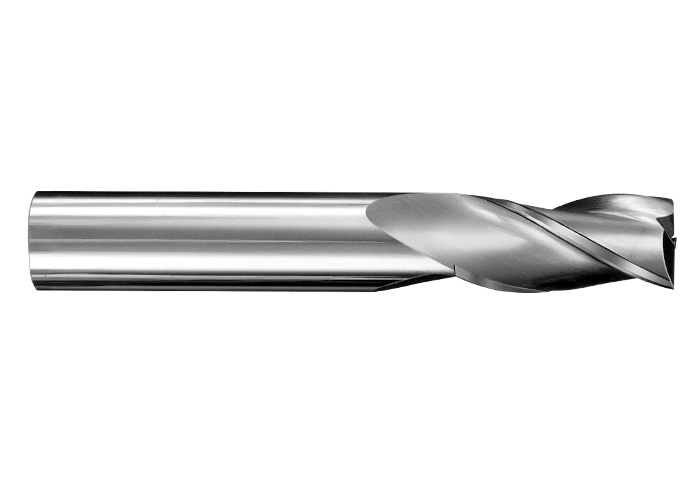

Ball Nose End Mill – These bits have rounded bottom and are typically used for carving 3 dimensional projects. When used properly they can leave a very smooth and detailed finish on your workpiece.

If you are just starting out, I would get a 2 flute 1/8″ and 1/16″ ball nose for your tool kit. These two sizes are very common and depending on the level of detail, you would have a bit for most requirements.

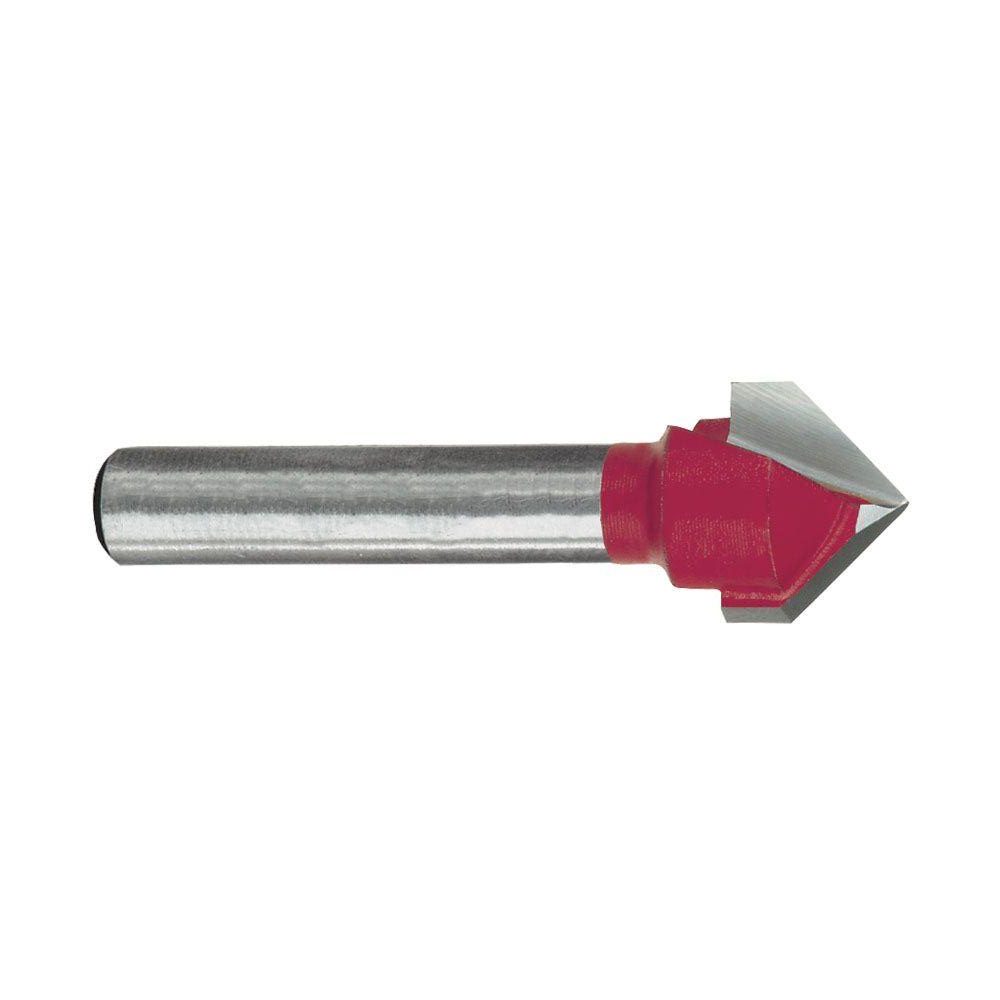

Engraving Bits – These bits will have a V point on the end are used for engraving materials for lettering or designs. Its suggested to have 1/8″ 90 degree and 60 degree engraving bits for your tool kit when you are starting out. These will give you a lot of flexibility for engraving options.

Additionally, if you have a CNC that can support 1/4″ shank bits, then its suggested to get a 1/2″ V router bit with a 1/4″ shank. These are commonly found at home improvement stores like Home Depot and Lowes. This 1/2″ V bit is perfect for sign lettering and when using a program like V Carve, you have the ability to do some really nice 3D lettering.

These are the most common bits that I suggest any beginner have in their tool box. As you gain more experience, you can add many more bits to your system in a variety of shapes and sizes for different applications. STEPCRAFT has a Starter Tool Set

that includes all of these bits which can be found HERE.

No. While there are some “general purpose” end mills that will cut aluminum, some end mills are designed specifically for plastic, foam, wood or other non-metal materials.

Yes, end mills can be resharpened, however you need a special sharpening grinder in order to do this properly. Sharpening bits makes more sense with larger diameter end mills that are very expensive. If you are paying to sharpen your bits then it does not make good financial sense to sharpen smaller bits (1/8″, 1/4″ or smaller). The smaller the diameter of the bit, the more difficult it will be to sharpen it as well. Many bits that you will use on a small CNC router are going to cost less than $40 and good quality carbide bits will last you a very long time, especially considering the workloads derived from smaller CNC systems.

As an example, if I have a 1/4″ end mill that I have used for a year and paid $29 for it, I would simply throw it away and buy another before I would spend $20 to have it sharpened.

The ball nose and square nose end mills are all carbide. The engraving blanks and diamond bits are HSS